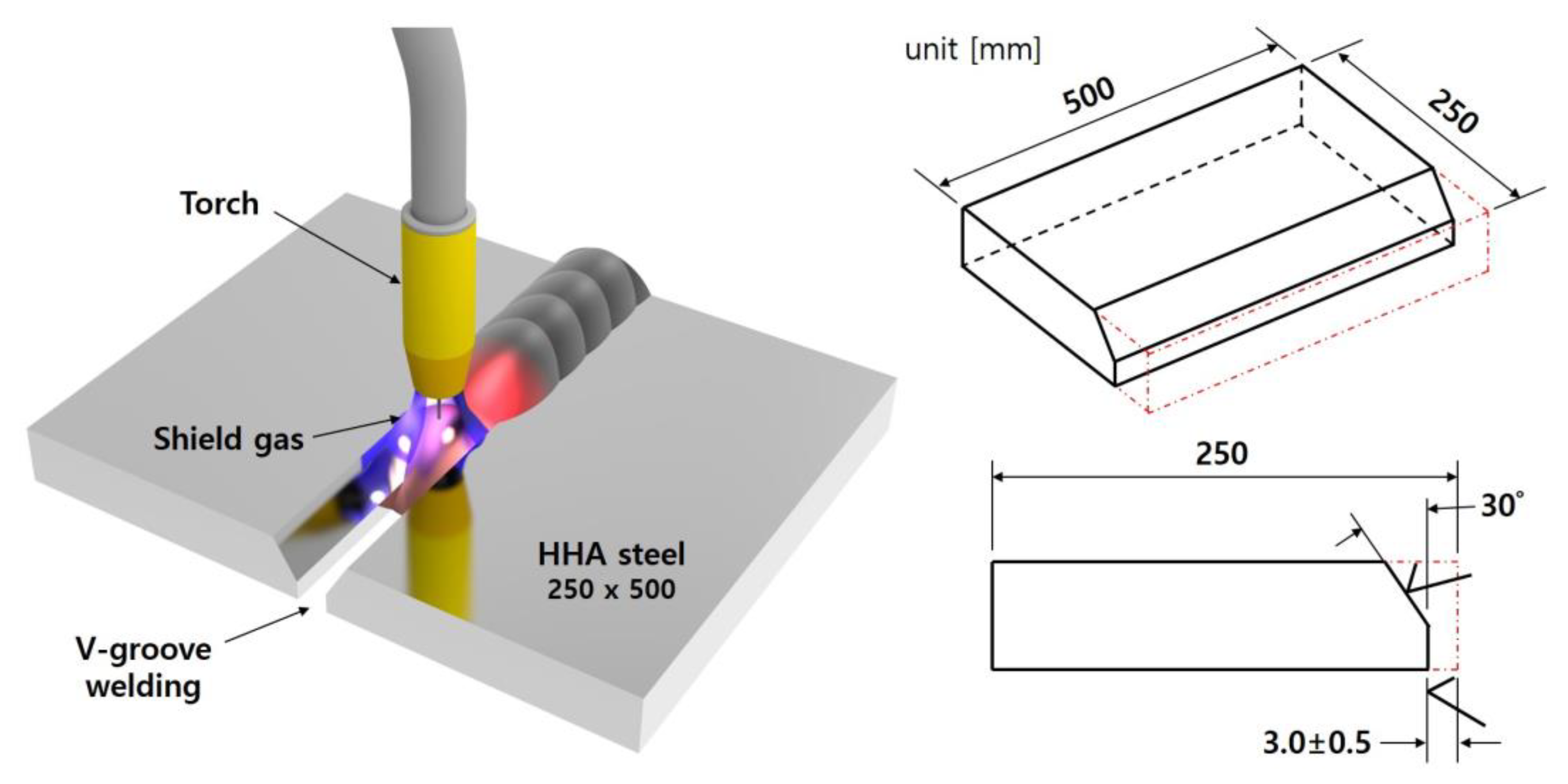

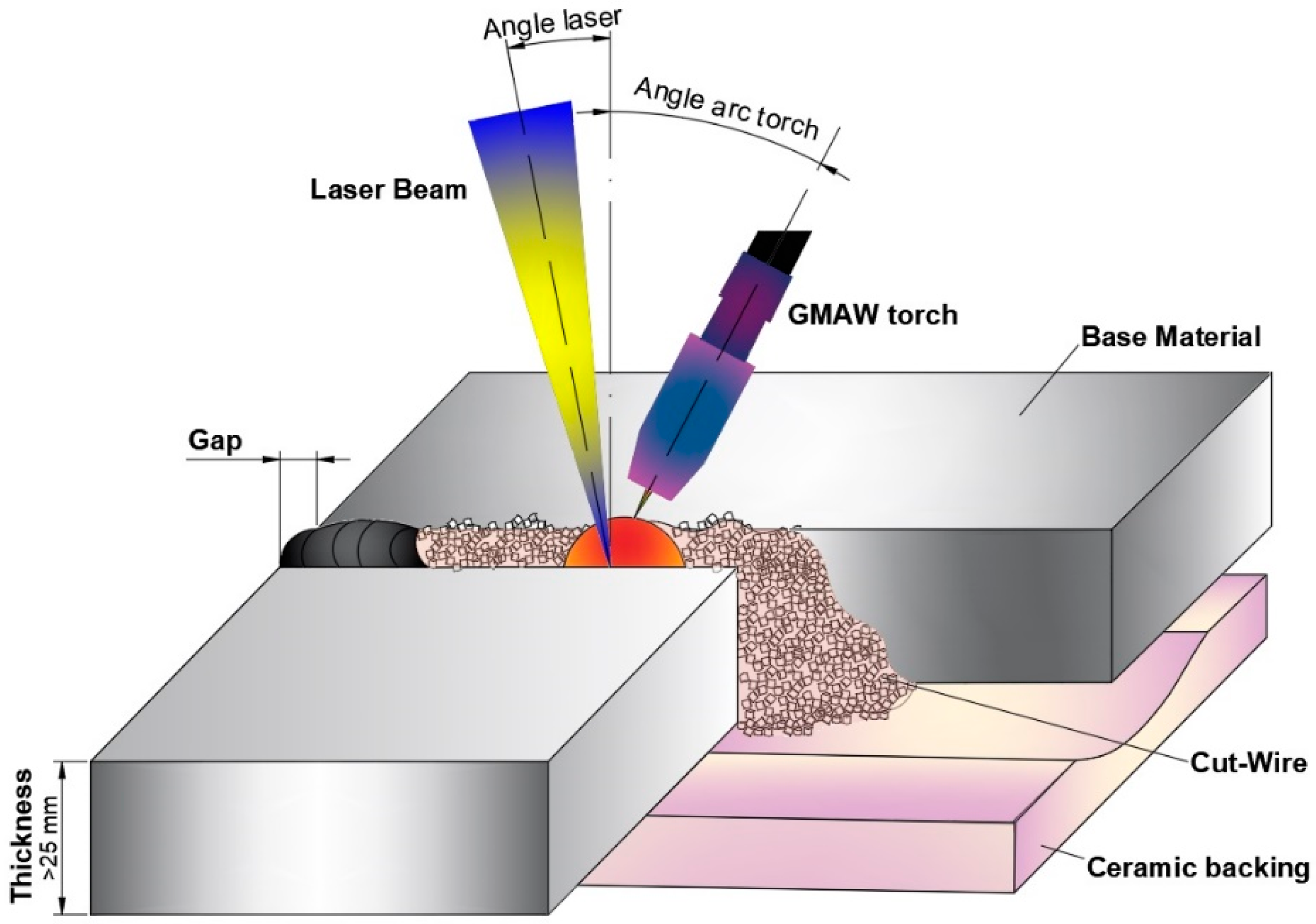

a) Joint design , b) Weld passes , c) X-groove and ceramic backing

4.5 (397) In stock

Download scientific diagram | a) Joint design , b) Weld passes , c) X-groove and ceramic backing from publication: The Effect of MAG and FCAW Methods on Microstructure and Impact Toughness of Multi-pass Welded Weldox 700 | In this study, high strength steel Weldox 700 was multi-pass welded using MAG (Metal Active Gas) and FCAW (Flux Cored Arc Welding) methods. During welding, by keeping heat inputs of these two methods close to each other, the effects of these methods on weld zone were | Welding, Notch and Steel | ResearchGate, the professional network for scientists.

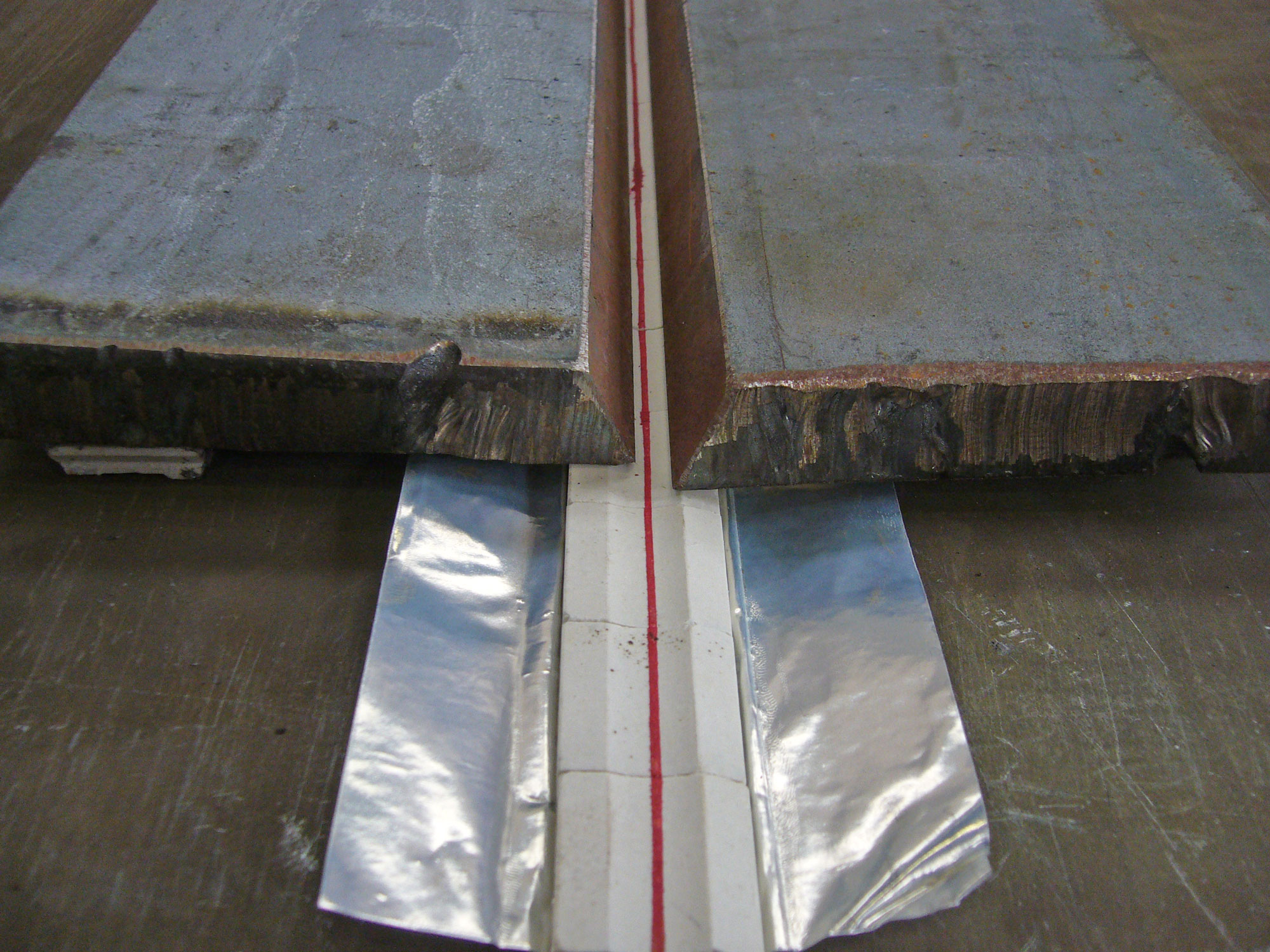

Ceramic Weld Backings with Servilattes

a) Details of the groove used; (b) a prepared joint ready for

Microstructure characterization of the weld cladding of clad steel

Design - Part 4 - TWI

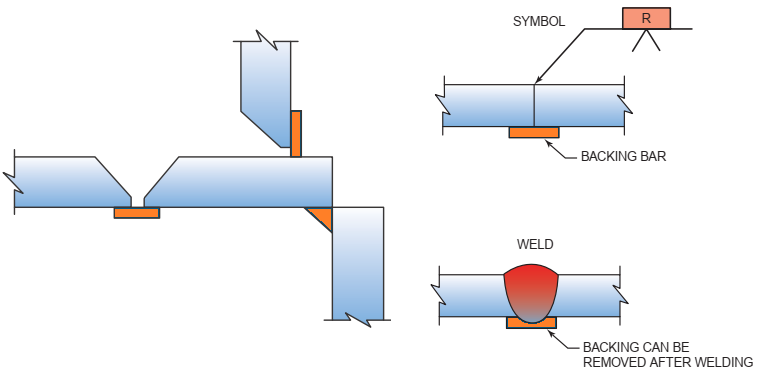

Backing in welding – AMARINE

Metals, Free Full-Text

Backing in welding – AMARINE

Metals, Free Full-Text

a) butt joint, (b) welding pass sequence, and (c) pipe and (d

What is back strip support of weld joint? - Quora

Dabotek - Alutape for Ceramic Welding Backing

Backing Plate /Baking Bar Welding में क्या होता है? What is Backing Plate in Welding?Why we use it?

All About Oil and Gas on LinkedIn: #backweld #backingweld #welding

i.img.com/images/g/b7gAAOSwvNthMQGj/s-l1200

i.img.com/images/g/b7gAAOSwvNthMQGj/s-l1200 12 Stag Bone Full Tang Fish Fishing Filet Fillet Camping Hunting

12 Stag Bone Full Tang Fish Fishing Filet Fillet Camping Hunting Abu Garcia Abu Garcia Fishing Reels in Fishing Reels by Brand

Abu Garcia Abu Garcia Fishing Reels in Fishing Reels by Brand Nadia Titeuf Nadia GIF - Nadia Titeuf Nadia Nadia Kiss - Discover & Share GIFs

Nadia Titeuf Nadia GIF - Nadia Titeuf Nadia Nadia Kiss - Discover & Share GIFs- Physics in Hindi for Android - Download the APK from Uptodown

Reelcraft 1/2 in. x 25 ft. A5825 OLP Premium Duty Spring Retractable Air/Water Hose Reel - Reel & Hose - John M. Ellsworth Co. Inc.

Reelcraft 1/2 in. x 25 ft. A5825 OLP Premium Duty Spring Retractable Air/Water Hose Reel - Reel & Hose - John M. Ellsworth Co. Inc.